| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

VARLIK MAKİNA SANAYİ İÇ VE DIŞ TİC. A.Ş.

Ömer Mah. Seciye Sok. No: 2 / Arnavutköy / İSTANBUL / TÜRKİYE

|

Contact Info: +90 212 798 2625

|

Hall: 11

Stand: 1117A

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

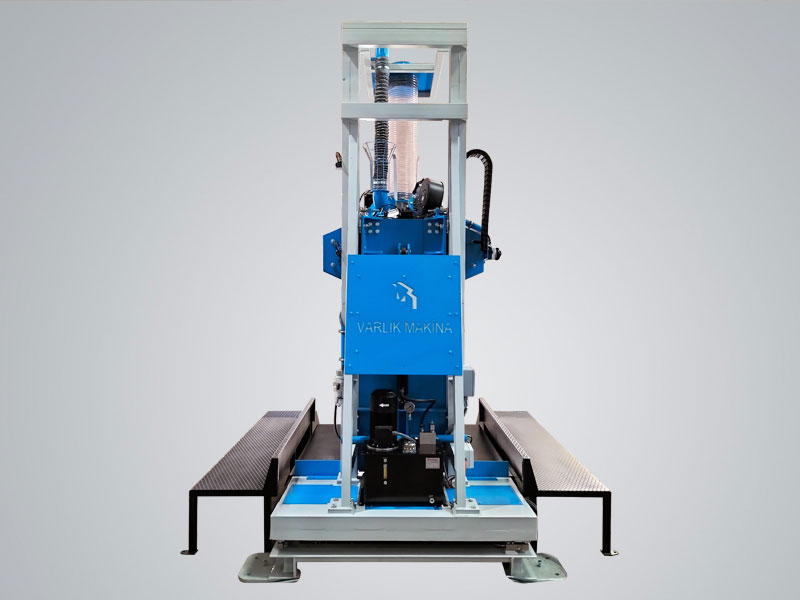

46 YEARS OF EXPERIENCE Varlık Makina offers to their customers not only machines and systems , but also offers Solution Engineering With its skilled 150 staff and 20 engineers, the company has a closed area of 25.000 m2 VARLIK MAKINA, has founded by Ekrem VARLIK in 1976 and now become one of the leader company in the World on the Dry mortar Production Plants , End Of Line , packaging solutions, and Turn Key Project Solutions. For more than 46 years, Varlık Makina has designed-manufactured -installed -Commisioned-handed over hundreds of turnkey Facilities from New Zealand to Argentina, Chile. Varlık Makina has successfully delivered dozens of projects of international companies (such as Sika, Basf, Parex, Lafarge Holcim, Mapei, Henkel, Fosroc...) around the world and still continues. Varlık Makina manufactures all processes of Raw Material Preparation, Crushing, Drying, Screening, Stocking, Dosing, Raw Material Transfer, Mixing, Packaging, Palletizing and Stretching processes with its own design and expertise and offers high quality and complementary solutions to its customers from a single source. Varlık Makina offers to their customers not only machines and systems , but also offers Solution Engineering We Believe that all the successful projects handovers will drive us further and keep our name one of the leaders in the World.

Our stretch hood machines are perfectly implemented for a wide variety of industries such as chemicals, minings, ceramics, minerals, beverages, food, feed, seeds , etc.

Offers the most suitable solution for packaging fine and ground products with medium and high densities and fluidity. The product in the machine reservoir is filled in to bag with 4 blade turbine driving and air support. Models with single, dual, triple and quad filling spouts are available according to capacity requirements. Machine filling speed varies according to the density and fluidity of the product.

These machines are suitable for filling valve bags. Product feeding is carried out with a impeller system or air system. Electronic weighing is performed via coarse and fine feeding. The device checks the previous bag and slows or accelerates the filling speed accordingly. The empty bag is placed in the first station automatically or manually by the operator. Fast or slow filling is carried out through 360° rotation of the machine body. Upon arriving at the bag release station, the bag is left on the belt and the filling procedure is completed.

User interface via HMI panel Automation Cabinet with Siemens S7-200 PLC Product feeding unit depending on the product Easy hanging height adjustments by operator panel via encoder for the different big bag sizes Empty bag blow -up by blower fan for better packing form and effective filling operation Automatic operation with one touch start after big-bag placing Automatic big bag - loops releasers after filling Heavy duty support platform

Palletizer robots with special attachments designed by VARLIK MAKINA can be custom-designed for your plant by our technical team according to the product type, production line, and process. Low cost, occupying less space in the plant, and also easy to adapt to varies sectors. Offering complete line solutions VARLIK MAKINA offers complete packaging solutions to robotic palletizer lines with integrated press machines and stretch hoods.

No represented companies found.

- VARLIK MAKİNA

TR

TR