| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

UNİTY GRUP TEKNOLOJİ A.Ş.

Eskoop Sanayi Sitesi B1 Blok No: 59/61/63 / Başakşehir / İSTANBUL / TÜRKİYE

|

Contact Info: +90 552 366 3056

|

Hall: 2

Stand: 210A

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Unity Automation, which was founded in Istanbul in 2007 with the aim of developing medium and large scale projects in the automation sector, bringing new automation technologies to our country and following the latest innovations in technology, has gained a respectable place in the automation world by showing steady growth with its professionalism, creativity, honesty and market development characteristics. Unity automation operates 24/7 solutions, support and production operations in 1.500 m2 service area with its 18-person team. With its continuous research and development policy, it is on its way to becoming the most important engineering-a company in Turkey with its staff of engineers, technicians and technicians who are in its team by managing its own infrastructure investments. Unity automation 52 domestic product that gives importance to domestic production since its inception it has increased annually and served more than 750 customers annually. Expanding its domestic and international market every day, Unity automation is approaching its targets with its exports to 16 countries. As a matter of fact, it is working to develop its dealer network quickly in order to reach its customers in support of these figures. Unity Automation, which does not compromise on quality, has CE Certificate in its products in an up-to-date way. Taking into account quality, environment and OHS notification as management, Unity Automation provides services to meet customer expectations with satisfaction, provide a sustainable trust policy and provide after-sales support.

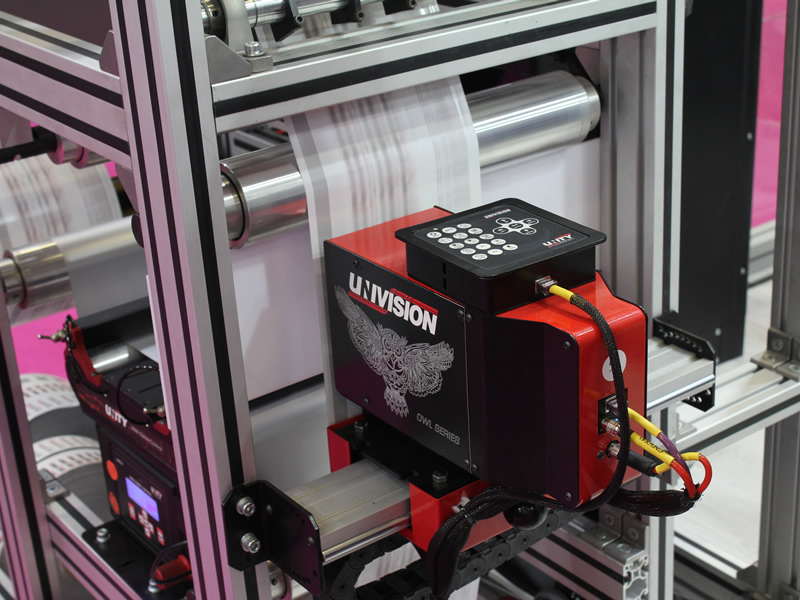

UNITY UVS-OWL are camera print monitoring systems that play a role in achieving high efficiency and strict quality standards throughout all stages of production, from operator monitoring of production to inspection (defect detection) and quality assurance. UNITY UVS-OWL is compared on the screen by the operator with an ideal print image predetermined on the synchronized machine (it can store up to 30 images in its memory) and the desired print on the line. During the comparison, printing errors that may occur at that moment are prevented with the help of the operator.

Web guide control: As a result of incorrect wrapping of the rolled material or due to mechanical problems, problems of moving left and right occur while the product is being processed. This causes wastage, decreased efficiency or poor quality. To prevent this problem, the web control system comes into play. Unity Web Control system follows the edge of the product and ensures that the product is unwound or wrapped on the same plane. It is a highly innovative system. Mechanical assembly is quite simple. It provides quality, speed and minimum waste rate. Provides high precision with stepper motor. Depending on the type of material, it can be used with an ultrasonic fork sensor, optical fork sensor or color sensor. Unity Web Guide control system, we have special production solutions according to the product type, width and condition of the machine. The edge control device corrects the edge of the bobbin that is damaged during unwinding and winding. Edge control is done by moving the bobbin left and right according to the information received from the sensor while winding or unwinding the product. In cases where this process is not mechanically possible in edge control, edge control is achieved by changing the direction of the product with the strip guidance system. Adapting the edge control system to the machine is quite simple. The edge control system provides great convenience and time for the machine operator. The edge control system generally consists of edge control device, edge control sensor, edge control motor, driver and limit switches. As a motor in the edge control system; Ac Motor, Servo Motor, Stepper Motor can be used. The edge control system can also be adapted to hydraulic or pneumatic systems. Color sensor (contrast sensor), ultrasonic fork sensor, or optical fork sensor can be used as sensors in the edge control system. Edge control system provides edge control with 0.01 mm precision.

The device can operate at temperatures between -40 and +80 degrees. A 4 x 20 LCD screen has been preferred on the instrument panel. Device box dimensions are 138 X 105 X 50 mm. The mounting method is in panel type structure. With its IP 24 protection class, it is dustproof and provides protection against low pressure water. It has 2 optocoupler contact outputs. The device has prox switch inputs for Loadcell, external start, external set value and machine start. The plug-in terminal group located at the back of the device is used for cable connections. It has 0-24V / 4A brake output. The minimum output resistance is determined as 5 OHM. WHERE IS UTC-03 TENSION CONTROL DEVICE USED? -Used to control winder solvent material flow in main inlet/outlet stages. -Used to control PLC or similar industrial devices. -It provides filling control of the product in the hygiene industry. UTC-03 TENSION CONTROL DEVICE APPLICATION AREAS -Process Automation -Wrapper - Unwinder -Printing -Plastic packaging and label industry -Production and technological lines -Tension control devices

Pneumatic air brakes; They are used to keep moving and rotating machine parts in constant tension or to stop them in a shorter time. Working principle; The system is driven by air, the diaphragm in the air tank pushes the pusher forward and the shoes hold the rotating disc. When the air is released, the thruster returns via the spring and the braking process is terminated. Purpose of pneumatic brake: Keeping the movement at constant tension by means of a proportional valve, Emergency stopping function of the moving mass, Ensuring stopping at certain times, Braking function at certain moment values, Usage areas: Iron-Steel Industrial Equipment, uncoiling-rewinding, tension control etc. They are used for a wide variety of purposes in Cable and Wire Winding Machines, Paper Industry, paper tension control, Packaging Machines, Textile Industry, Cement, Mining and Construction Industry.

UNITY H-SCOP 48 is a product used to examine regularly repeated movements. Used for surface inspection only. It makes it easier to detect surface defects throughout the entire production line. When elements move at high speed, it is impossible for the eye and mind to focus clearly on the shapes. H-SKOP 48 eliminates motion blur and allows operators to see the photo steadily. It is used as an effective control tool for these processes. In regularly repeated movements. In the printing and paper industry. In the packaging industry. Printing: Print quality and paper inspection, fold alignment, embossing quality. Converting: trimmed edge and hole analysis, surface inspection of adhesives and coatings, die-to-die registration, slitting/wrapping, cut quality. Paper: special paper, cut quality in finishing sections. Whether it is a printing or coating process, UNITY H-SCOP 48 is suitable to be used in these situations, especially when we need a quick measurement control or a quick general control.

No represented companies found.

- UNİTY

- ULAK

- UNIVİSİON

- UNELSİS

TR

TR