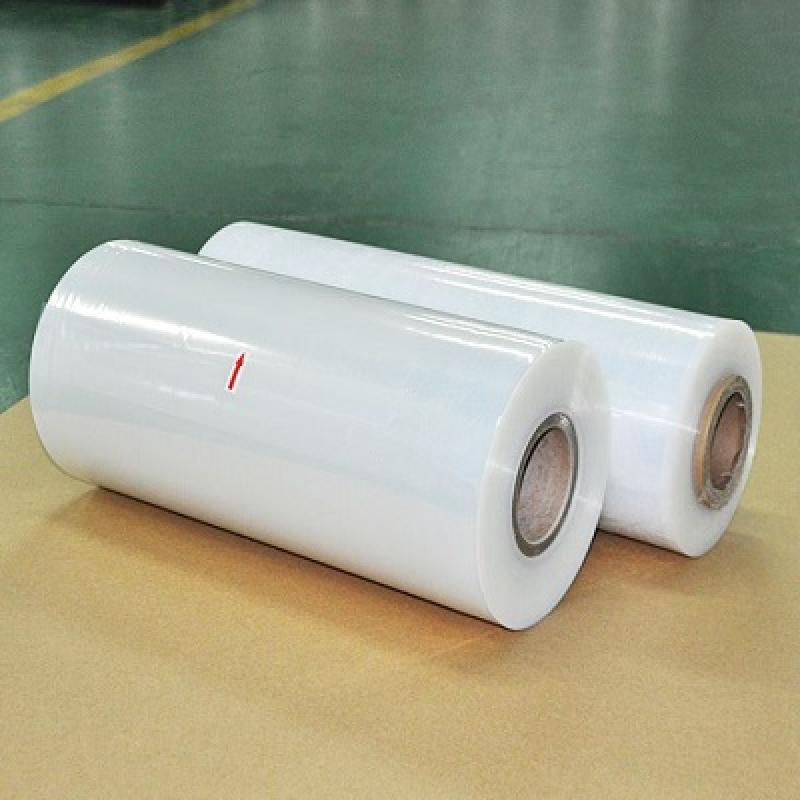

9 layers Co-extrusion PA/PE barrier film

9 layers Co-extrusion PA/PE barrier film

Category:

Films and foils, sheets and rolls, PET preforms, PET resin, raw materials and masterbatches, packaging chemicals, textile products and fibers

This product is provided by the company GREEN PACKAGING MATERIAL JIANGYIN CO.,LTD . Please contact for more information.

Product Description

Multi-layers Co-extrusion barrier film is generally produced using a multi-layer co -extrusion blowing process or casting process. Multi-layer co-extrusion has excellent barrier performance, mechanical properties, tensile forming performance, and heat sealing performance, and does not require additional compounding during the processing, nor does it involve printing ink, adhesives, and additive residues. Therefore, it is a relatively green and environmentally friendly technology Cost advantages in food packaging technology and processes.

Multi-layer co-extrusion barrier film refers to the use of three or more extrusion screws to melt and extrude resin raw materials with different functions, such as polyethylene, polypropylene, nylon, ethylene vinyl alcohol copolymer, etc., and then converge at the multi-layer co-extrusion die head through their respective flow channels. After blowing or casting, the film is cooled and compounded together to obtain a multi-layer co- extrusion film. This method combines and designs the advantages of different resins to produce films with comprehensive performance and meet different packaging needs.

Other Products of the Company

See AllVacuum pouch

Vacuum pouch

Similar Products

See AllALKOsafe™ two-piece induction liners ALKOsafe™ two-piece induction liners

ALKOsafe™

PET FOLYO

PET-PP FOİL

Aluminum Coils and Strips

Aluminum Coils and Strips

Aluminum Foil for Triangular Cheese