200L Drum Melter System

200L Drum Melter System

Category:

Coating And Laminating Machines, Transferring, Sizing, Cutting And Folding Machines

This product is provided by the company İDEALTECH MAKİNA SANAYİ VE TİC. LTD. ŞTİ. . Please contact for more information.

Product Description

Our 200-liter Drum Melter models represent the latest technology in melting thermoplastic and reactive hotmelt adhesives. With dual-pump functionality for independent weight control, a melting capacity of up to 100 kg per hour, and an easy-to-clean design, they are a preferred solution in industrial applications.

Additionally, using adhesives supplied in 200L drum packaging offers significant long-term cost advantages in terms of unit price.

Designed for melting a wide range of adhesives such as PUR (Polyurethane) hotmelt, EVA, PSA (Pressure-Sensitive Adhesives), PO (Polyolefin), and Polyamide, our 200L Drum Melter systems offer a more advanced alternative to conventional tank melters. Featuring multiple heating zones with independent temperature control, our drum melters vary by melting head configuration and throughput capacity.

Professional Solution for a Wide Range of Applications

Drum melter systems are widely used across industries such as product assembly, label lamination, insulation coating, profile wrapping, flat lamination, automotive door sealing, textile lamination, woodworking, and packaging — offering efficient and reliable adhesive solutions.

Unlike traditional tank melters, drum melters only heat the top layer of adhesive inside the drum, keeping the rest of the adhesive in solid form and preserving its chemical integrity. This makes the system ideal for sensitive adhesives like PUR and other moisture-reactive hotmelts, maintaining their bonding performance and thermal stability.

Other Products of the Company

See AllPiston Pump Tank Melting System

Piston Pump Tank Melting System

Assy & Igm Product Family

Piston-Assisted Idm-Gp Melter

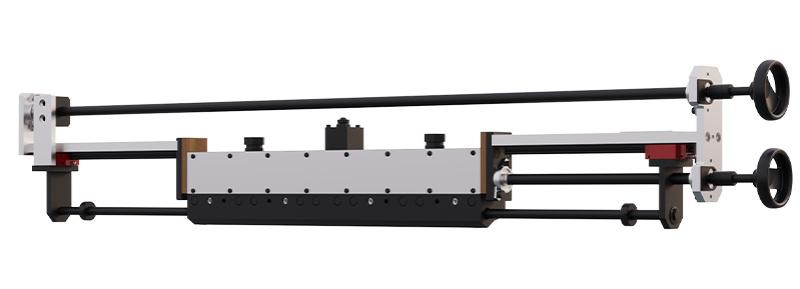

Slot Die Coating Head

Slot Die Coating Head

Automatic Adhesive Gun

Automatic Adhesive Gun

Similar Products

See AllASSY & IGM Product Family

Piston-Assisted Idm-Gp Melter

Slot Die Coating Head

Slot Die Coating Head

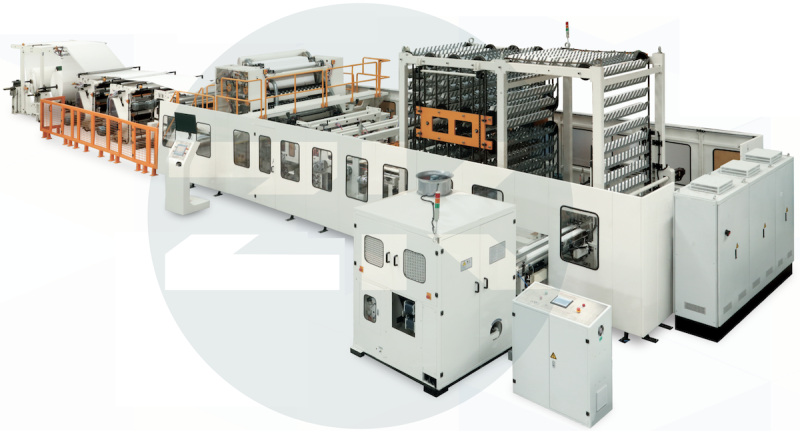

ZM-KM-H Facial Tissue Production Line

Facial Tissue Production Line

Piston Pump Tank Melting System