Automap Series - 100E/200E/200Exl/Mi̇ni̇/Ecoseal/Md250

FULLY AUTOMATİC MAP PACKAGING MACHİNIS

Category:

Packaging And Wrapping Machines, Auxiliary Equipment, Conveyors, Transport And Storage Systems

This product is provided by the company APACK AMBALAJ MAKİNE SAN VE TİC LTD ŞTİ . Please contact for more information.

Product Description

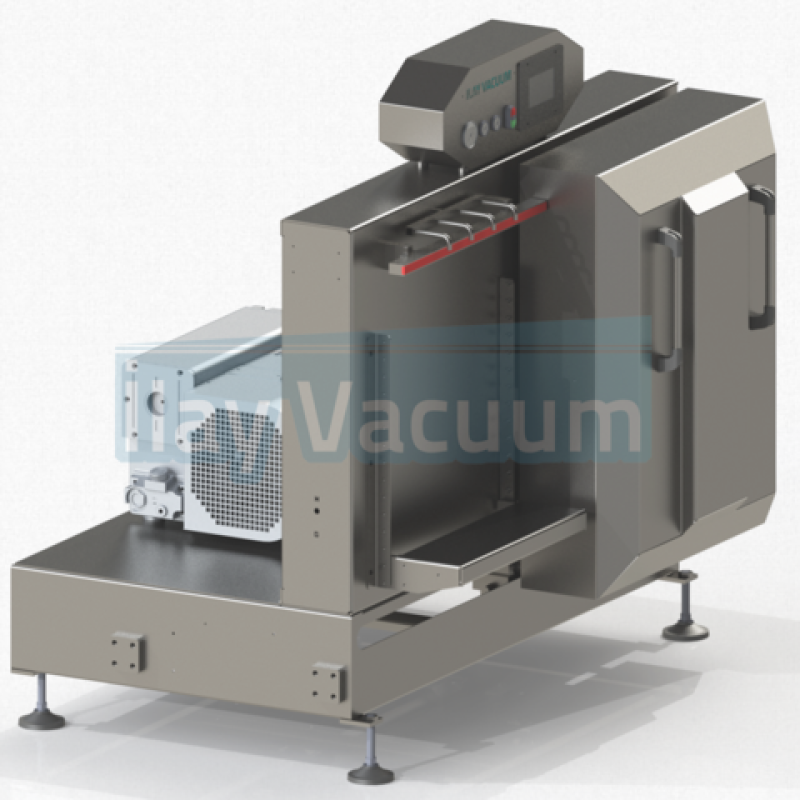

autoMAP series are machine systems that can meet all your packaging needs with fully automatic systems. The production lines cover all stages, starting from tray feeding, product filling, weighing, sorting, MAP sealing, labeling, collection and stacking. Its body is completely made of AISI304 stainless steel. The machine is very easy to use, maintain and clean.

It is suitable for the use of single and multi-compartment trays. With the special ZERO2XYGEN software, gradual vacuum processes can be easily applied. Molds can be easily changed by trained personnel.

It is fully compatible with all kinds of packaging system accessories.

Multi-Function Control System

With its touch screen, all stages of production and possible error messages are instantly displayed on the screen. All processes can be adjusted in accordance with all kinds of trays and films. With the multi-program memory, it is possible to easily switch to different production models. The automation unit, which monitors and controls all kinds of production lines, immediately warns about possible errors, misuses and plumbing malfunctions and protects the system. The operation of the accessories placed on the line can be done from the autoMAP control panel.

System controls can be made by accessing all autoMAP series machines over the internet.

autoMAP100Mini

It is a useful model designed for manufacturers with limited working space. It includes all the features of the autoMAP series. It provides great convenience in terms of both budget and settlement.

autoMAP100E (Wide)

The volume and mold dimensions of the standard autoMAP100 structure have been expanded for large packages other than general use. Machine dimensions, carriers and operating structure are redesigned according to your packaging needs and produced in sizes suitable for demand.

autoMap200E (Wide)

The 200E model has been designed by expanding the standard autoMAP200 structure, volume and mold dimensions for large packages outside of general use. Machine dimensions, carriers and operating structure are redesigned according to your packaging needs and produced in sizes suitable for demand.

EcoSEAL100Mini

It is suitable for attaching all kinds of accessories like all fully automatic machine models. Automatic Tray Feeding, Automatic Weighing and Filling, UV Disinfection, Metal Detector, Printer, Barcode Applicator etc. All packaging line accessories are automatically operated within the EcoSEAL 100Mini without any problems.

It is the most suitable solution for your food/medical packaging that does not require vacuum and gas.

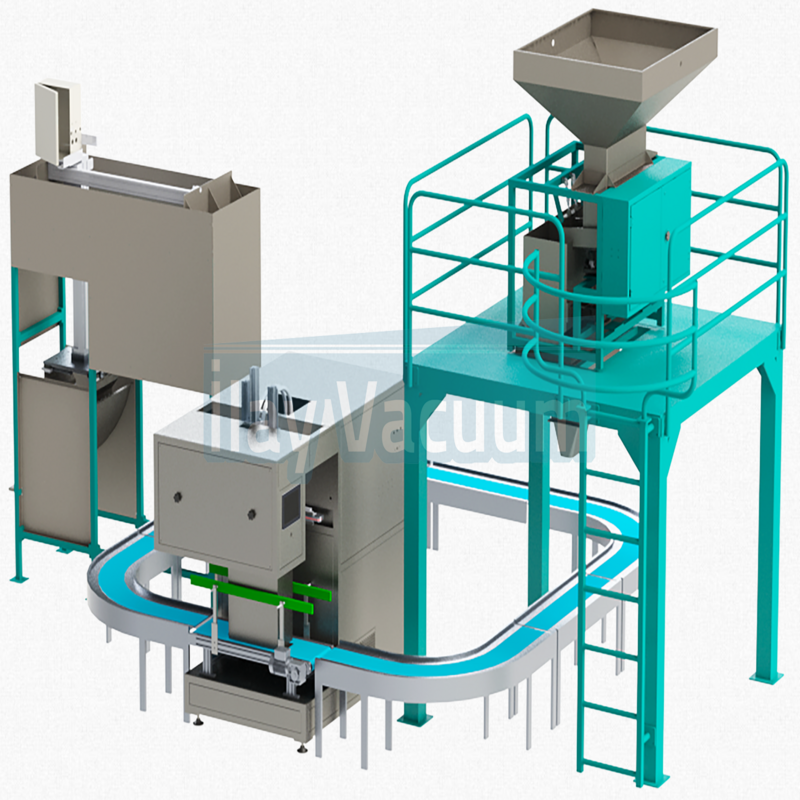

autoMAP MD250

These are our fully automatic MAP packaging lines that can fully meet your need for high-capacity mass production in MAP packaging. Operation starts from tray feeding, covers all stages such as filling, weighing, sorting, MAP sealing, labeling, collection and stacking of the product.

Other Products of the Company

See AllFully Automatic Tray Sealer

Ecoseal 100 Mini

Fully Automatic Map-Skin-Cardboard Packaging Machine

Automap Series

Fully Automatic Map-Skin-Cardboard Packaging Machine

Performa Series

Semi Automatic Map-Skin-Cardboard Tray Sealer

Map25

Similar Products

See AllFully Automatic Jar Sealer

Autoseal Js230

Vacuum Packaging Machines

Vacuum Packaging Machine Vertical Il65 - Double Chamber

Vacuum Packaging Machines

Full Automatic Vacuum Packaging Machine Line Il2024 - External Type

Rigid Box Making Machine