| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

OK AMBALAJ PLASTİK SAN. VE TİC. A.Ş.

Kayapa OSB Karanfil Sok. 5A / Nilüfer / BURSA / TÜRKİYE

|

Contact Info: +90 224 261 5806

Web: https://okifoil.com

|

Hall: 5

Stand: 523A

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

OK Ambalaj is founded on year 1980 in Bursa / Turkey. Our company has initially operatedin various trade branches then started manufacturing plastic packaging at the same address since 1998. In the first years, it has supplied products such as PE Bags, shrink film, textile and automotive sectors in the local market. In the following period, its staff, capacity and market share have continuously increased. Our company was restructured in 2016 in machinery park and product range and today it has been moved to its modern facilities in Bursa Kayapa Industrial Zone. Today, we are supplying technical films to various sectors using co/ex blown film technology. Besides, it is capable of producing multi-layer flexible packaging with solvent-based lamination technology. With the investment made at the end of 2019, we have installed our Windmöller&Hölscher Extrusion Blown line in May 2020 and it has head towards to the export market and start exporting more than 30 countries today. We work with a staff of 60 people who have embraced our experience. Our manufacturing plant has a production capacity of 1000 tons per month. We are continuing our investments that will expand the product range and increase the production capacity by prioritizing to Quality First and Customer Satisfaction. We continue to produce, develop and become an ideal business partner for our customers with our experienced, trained and energetic personnel. Our goal is to reach world-wide recognition in flexible packaging and with our Professional staff we are approaching our targets with every passing day. Ok Ambalaj has adopted the principle of developing its market in international platform with keeping quality service concept on world standard. We believe that happy customers come after perfect product so we always try to catch newest technology.

Polyethylene (PE) Lamination Film used for packing and wrapping food and pharmaceutical products. Co-extruded Films come in up to 9 layers of film with one/ both-side treated. Films maintain seal-ability and endure strong track force on high-speed lines and Form-Fill-Seal (FFS) machines. Films with 100% virgin FDA-approved PE are designed with excellent transparency, tearing resistance, chemical & grease resistance. Typical end Uses ; Lamination with alu foil (i.e. coffee packs) / Lamination with OPP/PET films (i.e. frozen food, wet-wipes) / PRINTON (soft detergent packing) / FFS BAGS

Tubular or Gusseted co-ex polyethylen films for the production of FIBC liners Antistatic films Permanent Antistatic Films Conductive films Opaque white and colored films We can offer at OKI FOIL various solutions to customer needs with FIBC Liner Films manufactured with different structures and films such as LDPE, MDPE, HDPE, LLDPE, Aluminum, and PET, conductive and antistatic.

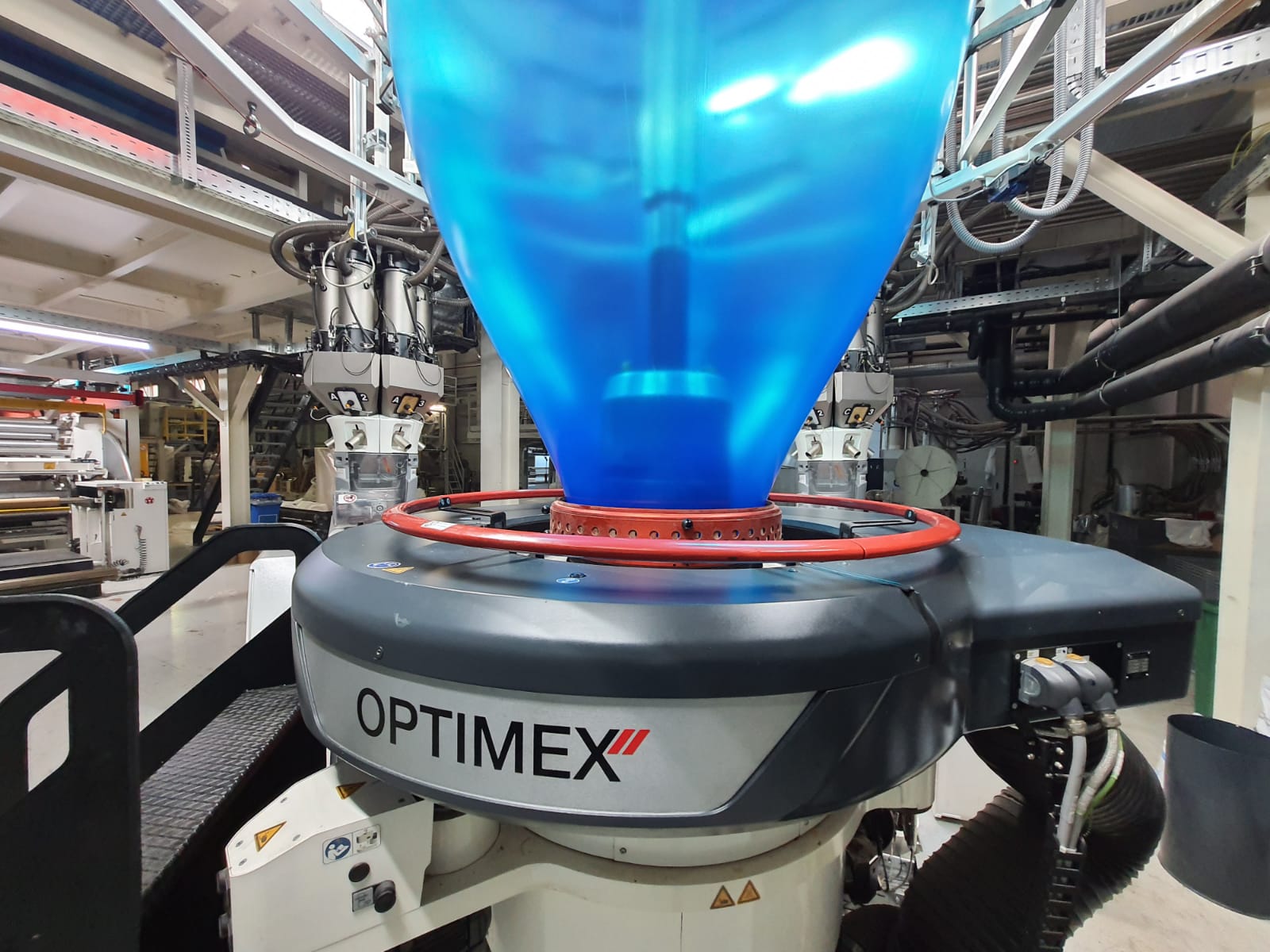

OK Ambalaj manufactures 100% recyclable Stretch Hood Film that tightly secures products to pallets for ease of use in high-speed lines using automated pallet packaging systems. Stretch Hood Film keeps loads in storage and transit covered and protected from dust, dirt, and moisture. Its superior seal strength and excellent tear and puncture resistance safeguard against trauma and product tampering, while also offering 5-6 sided protection. The transparent film allows for high brand visibility and lets product codes be scanned without the need to open the pallet, making logistics easy. With a max film circumference of 5400 mm and an engineered stretch ratio of up to 160%, Stretch Hood Film is strong and adaptive enough to palletize large loads with ease. Custom film clarity and printing are also available for Stretch Hood Film.

Produced by solvent-based lamination technology. It can be heat-sealed directly on foamed/bubbled pe sheets. It can be laminated with printed PET/OPP to make triplex structures in economical & fast way.

PE PROTECTIVE SHEET From 1mm to 4mm Up to 2000mm UV Proof Weather Proof Impact Proof Termite Proof 100% Recyclable WHY use OKIflex? Provides you best cable protection & saves you money and time. OKIflex is consist of two layers. First layer is UV resistant can be any color. White side can be decorated with flexographic print up to 8 color upon request. PE film is laminated to second layer UV resistant as black carrier sheet. OKIflex is essential where you need extra protection against the external impacts. It is mostly used to protect the cable wire drums against the forklifts touches and damage of UV light in case of exterior storage.

No represented companies found.

- OK AMBALAJ

- OKIFOIL

- OKIFLEX

TR

TR